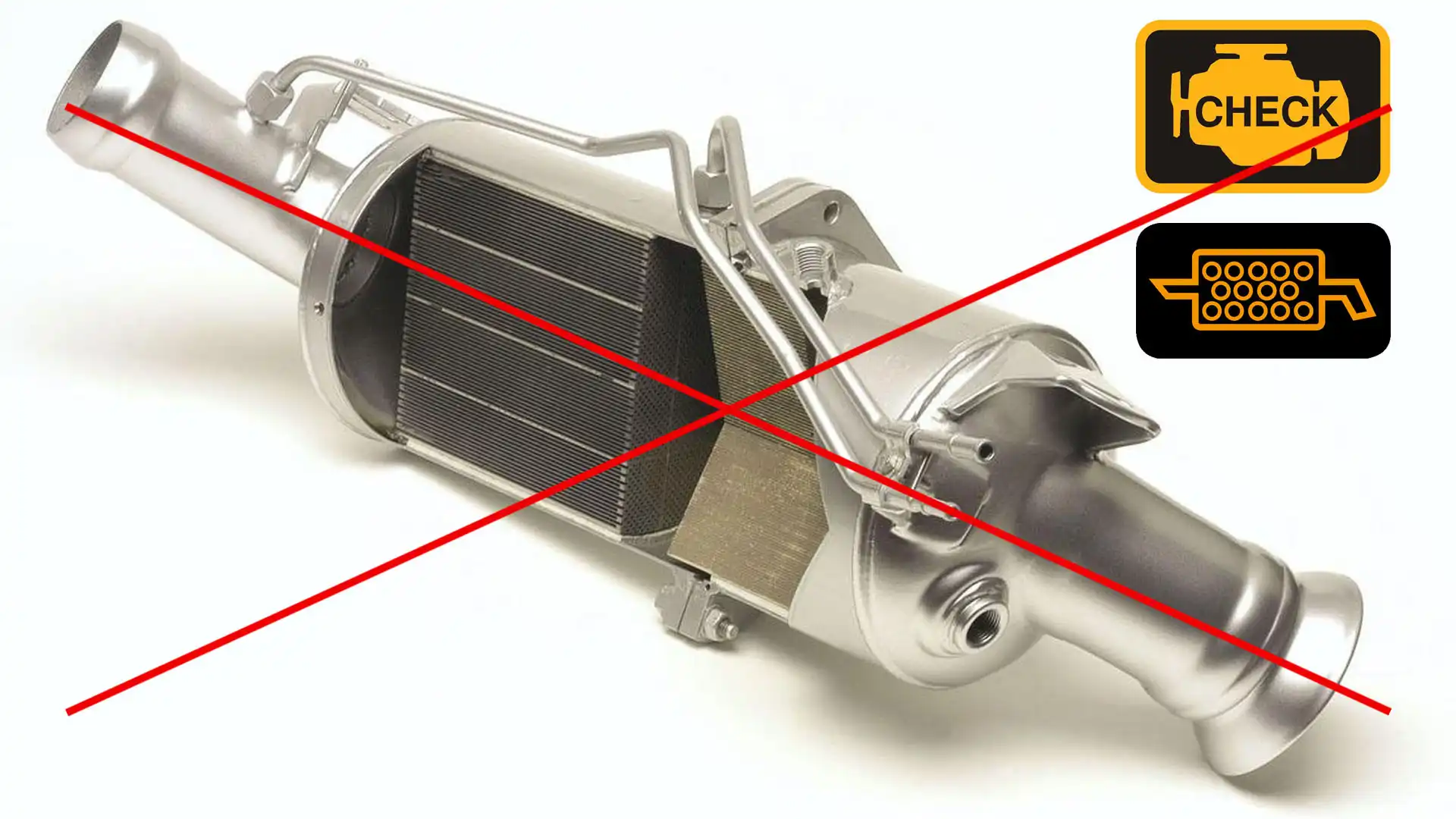

DPF Off: Maximize Power, Minimize Restrictions!

DPF delete also increases the efficiency of gas evacuation since it removes the constraints typically placed on exhaust gases, facilitating easier gas evacuation and lowering backpressure.

DPF deletes are performed on diesel vehicles used for off-road or competitive purposes, as it is illegal to remove emissions control devices from cars driven on public roads.

Some vehicle owners may choose to perform a DPF delete on their road-going vehicles to improve performance and fuel economy despite the legal and environmental implications.

DPF Delete: Detailed Information and Map Modifications

For automotive engineers focused on engine tuning, grasping the complex task of adjusting ECU software for DPF removal is essential. This task requires adjusting various key maps and parameters within the engine control unit to ensure optimal performance. Here are the key research details:

1. DPF Regeneration Maps

- Function: Manage the soot burn-off process in the DPF (Diesel Particulate Filter).

- Modification: Disable rebuilding by setting the parameter to zero or turning off the trigger.

2. Soot Load Maps

- Function: DPF tracks soot buildup and causes regeneration.

- Modification: To stop regeneration, either set the parameters to zero or turn off the triggers.

3. Pressure Sensor Maps

- Function: Examine the pressure difference that exists across the Diesel Particulate Filter (DPF).

- Modification: Bypass or alter in order to maintain an always low pressure differential.

4. Temperature Maps

- Function: Monitor the temperatures of exhaust gases to manage the DPF.

- Modification: Make changes in the limits or turn off the monitoring system so that no regeneration triggers are raised.

5. Diagnostic Trouble Code (DTC) Maps

- Function: It's important to maintain a record of DPF-related codes.

- Modification: To prevent error messages, make sure to disable or eliminate any DPF-related diagnostic trouble codes (DTCs).

6. Maps of exhaust gas recirculation (EGR)

- Function: EGR system interacts with the DPF system.

- Modification: Optimized EGR settings for performance without DPF, which may reduce flow.

7. Fuel Injection Maps

- Function: The timing and amount of fuel injection need to be fine-tuned.

- Modification: Adjustments to control combustion can minimize, if not completely avoid, soot in order to optimize combustion without DPF.

A Few Advanced Considerations

Compliance with OBD-II readiness and readiness

- DPF-related readiness monitors should always show "Ready".

- Check that other readiness monitors are functioning normally to ensure compliance with OBD-II.

Calculated Nominal Values (CNV)

- CNVs should be recalculated in light of the revised exhaust configuration:

- Exhaust backpressure expectations need to be adjusted

- Mass airflow sensor readings need to be modified

- Oxygen sensor feedback parameters need to be updated

Pre-Removal ECU Preparation

1. Delete all fault codes related to the DPF

2. The soot load counter should be reset to zero

3. Clear active regeneration history and active interval timers

4. Reset the ash accumulation counter on the DPF

Professional Diagnostic Equipment

- Modifications and verifications must include the following:

- Capabilities for OE-level communication

- Real-time monitoring of data

- Capabilities for advanced coding and flashing

Technical Process Workflow

1. Registration and purchase of credit by customers

2. ECU read-out performed by the customer

3. Submission of files to the Service Portal

4. Review from engineer for Particular Requirements

5. Modification of the file and uploading the same in the customer portal

6. Client download and ECU flashing.

7. Support through the ticketing system as needed.

Our efficient processes ensure a quick response. Our efficient process ensures fast turnaround, typically under 30 minutes, and complex files are processed within one hour.

Critical Considerations

- Emissions Compliance: Removing DPF will change the greenhouse gas emissions profile. The engine is designed solely for off-road or racing purposes.

- Engine longevity: Measurements are optimized to maintain engine health even after the DPF is removed.

- Performance Benefits: Increased horsepower and torque due to reduced back pressure.

- Legal Environmental Impacts: Consider local regulations and environmental impacts before proceeding.

As a professional calibration engineer, We ensure that each DPF exhaust file is tailored to the specific engine model. Considering the specifications of the turbocharger. Fuel system capacity and overall powertrain architecture This comprehensive approach achieves desired vehicle performance modifications and also maintains credibility.

DPF OFF FAQs

How do you modify the lambda sensor feedback loop to compensate for the altered exhaust flow post-DPF removal?

By accounting for the increased exhaust flow, we adjust the lambda target values as well as the closed-loop fuel trim parameters. This usually means increasing the allowed range of maximum short-term fuel trims and adjusting the returned limits of the long-term fuel trims.

What strategies do you employ to prevent torque limiting when disabling DPF-related parameters in modern ECUs?

We alter the torque model located in the ECU, especially with respect to the maximum torque values allowed and the levels of torque intervention thresholds. Often, this requires remapping the engine load calculation in order to avoid false overload warnings.

What can be done to alleviate potential problems with EGR cooler efficiency after DPF removal, especially for engines that generate high EGR rates?

Typically, we reduce EGR rates to compensate for higher exhaust gas temperatures. To maintain the best cooling performance, we can change the EGR cooler bypass strategy and adjust the EGR temperature threshold.

How do you recalibrate the mass airflow sensors to account for changes in exhaust backpressure?

The MAF sensors need to be scaled up to compensate for the increased airflow, so the scaling tables are adjusted accordingly. This typically entails changing the volumetric efficiency maps and air mass equations embedded in the ECU.

What are the best ways to optimize combustion efficiency without DPFs?

We generally adjust the injection timing slightly faster to take advantage of the reduced exhaust back pressure. The timing map has been adjusted to optimize the air-fuel ratio throughout the rpm and load range. This often results in slightly low amounts of ingredients.

What approach do you take to disable DPF regeneration cycles without triggering failsafe modes in the ECU?

We modified the soot load calculation algorithm to set constant values for the DPF-related sensors and disable the regeneration catalyst. To avoid failsafe modes, we might also have to circumvent some of the ECU's safety checks.

How do you handle OBD-II readiness monitors for emissions-related systems after DPF removal?

We modified the readiness verification criteria for DPF-related tests by setting them to display. For other exhaust systems, always use "complete." We will adjust monitoring parameters to ensure that the system works properly despite changes in exhaust configuration.

Do you employ any strategies to prevent excessive exhaust gas temperatures without the DPF?

We alter the fuel injection strategy to minimize post-injection losses and change the timing of the main injection to achieve maximum combustion temperatures. On the other hand, the EGR rate may be elevated at certain conditions to assist in regulating exhaust temperatures.

What changes in boost control parameters should be made after removing the DPF to account for the increased exhaust restriction?

We revise the boost control map so that the reduction in backpressure can be utilized and higher boost pressures can often be accepted. Our overboost protection parameters are also adjusted as a result of the wastegate duty cycle maps.

What methods do you use to disable or modify the differential pressure sensor inputs without triggering fault codes?

We usually apply a predetermined low value to the differential pressure sensor inside the ECU. We ignore the corresponding DTC and change the sensor's plausibility checks so that no fault code is present.

When removing DPFs, how do you address possible changes in turbocharger performance characteristics?

We adjust the VGT position maps according to the new exhaust flow pattern to improve the turbo response and efficiency. Such activities involve repositioning the vane at low RPMs to the desired angle to speed up the spool and altering high RPM positions to prevent the engine from overspeeding.

What approach do you take to recalibrate the EGR system to maintain optimal NOx control without the DPF?

Generally, we raise the overall EGR rate to compensate for the DPF NOx reduction effect's shortfall. This entails altering EGR maps over different loads and their corresponding RPMs, as well as changing EGR cooler bypass strategies.

How do you modify the engine load calculation to account for the changed exhaust system dynamics?

We modify the volumetric efficiency maps and the air mass calculation procedures to incorporate the novel features of the exhaust flow. In most cases, this entails modifying the ECU's control tables to convert intake manifold pressure to load.

When disabling post-injection events used in DPF regeneration, how do you prevent oil dilution?

We have completely or significantly reduced the late-cycle fuel injection events used for DPF regeneration. We may also adjust oil change interval recommendations to reflect changing operating conditions.

What is your approach to the handling of manufacturer-specific encrypted ECU parameters related to the DPF?

We use special decoding tools and algorithms to achieve these parameters. In cases where it cannot be edited directly, We can use simulation techniques to avoid or replace encoded functions.

What methods do you use to optimize cold start strategies after removing the DPF and its associated warm-up benefits?

We alter the cold start fuel enrichment maps and the parameters of the idle speed control to counteract the changes in the exhaust thermal properties. A warmer-up phase may need to be prolonged, and catalyst light-off strategies may need to be adjusted.

What approach do you take to recalibrate the fuel trim values to maintain optimal air-fuel ratios across the entire operating range?

We are expanding the acceptable range for short-term fuel trimming and adjusting long-term fuel trim limits. By modifying the base fuel maps, we provide more accurate starting points, thus reducing the need to make large trim adjustments.

How do you modify the torque models in the ECU to account for the increased exhaust flow and potential power gains?

We recalibrate both the estimated and requested torque maps based on new airflow characteristics. This includes modifying the torque limiting table and adjusting the torque-based boost control strategy.

How do you ensure long-term reliability and prevent premature turbocharger wear in high-mileage engines after DPF removal?

In the case of high-mileage engines, we adopt more conservative boost control strategies, shaping limits on the maximum boost pressure. We also set the oil temperature and pressure limits higher to enable more aggressive action earlier and include cooling-down strategies for turbochargers to avoid the oil coking inside the bearings.

What are the most common fault codes related to DPF problems?

DPF-Specific Codes:

- P2002: Diesel particle filtration efficiency is below the limit.

- P2452: Pressure Sensor "A" Circuit Low for Diesel Particulate Filter

- P2453: Pressure Sensor "A" Circuit High for Diesel Particulate Filter

- P2454: Circuit Interruptor for Diesel Particulate Filter Pressure Sensor "A"

- P2455: Pressure Sensor "B" Circuit Low for Diesel Particulate Filter

- P2456: Pressure Sensor "B" Circuit High for Diesel Particulate Filter

- P2457: Circuit Interruptor for Diesel Particulate Filter Pressure Sensor "B"

- P2458: Duration of Diesel Particulate Filter Regeneration

- P2459: Frequency of Diesel Particulate Filter Regeneration

- P2463: Soot Accumulation in the Diesel Particulate Filter

- P242F: Ash Accumulation and Diesel Particulate Filter Restriction

- P244A: Insufficient Differential Pressure for the Diesel Particulate Filter

- P244B: Insufficient Differential Pressure for Diesel Particulate Filter

DPF Regeneration Codes:

- P2080: Exhaust Gas Temperature Sensor Circuit Range/Performance

- P2084: Exhaust Gas Temperature Sensor Circuit Intermittent

- P2031: Exhaust Gas Temperature Sensor Circuit Low (Bank 1 Sensor 2)

- P2032: Exhaust Gas Temperature Sensor Circuit High (Bank 1 Sensor 2)

- P2033: Exhaust Gas Temperature Sensor Circuit (Bank 1 Sensor 2)

- P2470: Diesel Particulate Filter Regeneration Status.

Related Exhaust System Codes:

- P0470: Exhaust Pressure Sensor Malfunction

- P0471: Exhaust Pressure Sensor Range/Performance

- P0472: Exhaust Pressure Sensor Low

- P0473: Exhaust Pressure Sensor High

- P0474: Exhaust Pressure Sensor Intermittent

EGR System Codes (often related to DPF issues):

- P0400: Excess flow of exhaust gas recirculation

- P0401: Exhaust Gas recirculation flow somewhat detected

- P0402: Exhaust Gas Recirculation Flow Too High Is Detected

- P0403: Erratic Processing In The Exhaust Gas Recirculation Circuit

- P0404: Exhaust Gas Recirculation Circuit Range or Performance

Fuel System Codes (Can Affect DPF and Engine Performance):

- P0087: Fuel Rail/System Pressure – Below Range

- P0088: Fuel Rail/System Pressure – Above normal

- P0191: Fuel rail Pressure sensor circuit Range or Performance

- P0201-P0206 “Injector Circuit Malfunction (Cylinder 1-6)”

NOx Sensor Codes (related to emissions control):

- P220A: NOx sensor circuit limits/display

- P220B: NOx sensor circuit low

- P220C: NOx sensor circuit high

- P2000: NOx Adsorber Efficiency Below Threshold Bank 1

Diesel Exhaust Fluid (DEF) System Codes:

- P20EE: SCR NOx is below the catalytic efficiency limit.

- P203F: Reduction level too low

- P204F: Reductant system performance

Exhaust Gas Temperature ( EGT) Codes:

- P0544: Exhaust Gas Temperature Sensor Circuit (Bank 1 Sensor 1)

- P0545: Exhaust Gas Temperature Sensor Circuit Low (Bank 1 Sensor 1)

- P0546: Exhaust Gas Temperature Sensor Circuit High (Bank 1 Sensor 1)

- P0547: Exhaust Gas Temperature Sensor Circuit (Bank 2 Sensor 1)

- P0548: Exhaust Gas Temperature Sensor Circuit Low (Bank 2 Sensor 1)

- P0549: Exhaust Gas Temperature Sensor Circuit High (Bank 2 Sensor 1)

- P2031: Exhaust Gas Temperature Sensor Circuit (Bank 1 Sensor 2)

- P2032: Exhaust Gas Temperature Sensor Circuit (Low Bank 1 Sensor 2)

- P2033: Exhaust Gas Temperature Sensor Circuit High (Bank 1 Sensor 2)

- P2034: Exhaust Gas Temperature Sensor Circuit (Bank 2 Sensor 2)

- P2080: Exhaust Gas Temperature Sensor Circuit Range/Performance Bank 1 Sensor 1

- P2081: Exhaust Gas Temperature Sensor Circuit Intermittent Bank 1 Sensor 1

- P2082: Exhaust Gas Temperature Sensor Circuit Range/Performance Bank 2 Sensor 1

- P2083: Exhaust Gas Temperature Sensor Circuit Intermittent Bank 2 Sensor 1

- P242A: Exhaust Gas Temperature Sensor Circuit (Bank 1 Sensor 3)

- P242B: Exhaust Gas Temperature Sensor Circuit Range/Performance (Bank 1 Sensor 3)

If you have further questions about DPF problems, do not hesitate to ask us

(Note: It is recommended that you consult an expert for more information on the legal and technical aspects of DPF removal. This process can void your vehicle's warranty and cause environmental damage.)